A course for budding inventors

(The Star, 2 April 2021)

The transmission electron microscope, one of the state-of-the-art analytical instruments at UTP, produces high-resolution imaging technique that yields information on the morphology, crystal phase, crystal structure and defects.

CARBON fibre composites for lighter vehicles, biomaterials as parts to replace human joints and limbs, and pipelines and materials that can withstand the pressures and depths of deepwater oil and gas exploration and production – these are just some of the breakthroughs of materials engineering.

Manufactured materials can be found in nearly every aspect of modern life – from the metals and alloys in our cars, to the plastics, ceramics and composites in our homes.

Think about the products in your daily life and chances are most are the result of material innovation from recent years or going back thousands of years.

Those keen to explore this field of study (materials engineering) can take the first step at Universiti Teknologi PETRONAS (UTP).

The course is for inquisitive minds, problem solvers or budding inventors, says Puteri.

The course is for inquisitive minds, problem solvers or budding inventors, says Puteri.

“Materials engineering is the study of the different classes of materials such as polymers, metals, ceramics and other advanced materials such as composites, nanomaterials, and biomedical and smart materials – with a view to improve their performance or to create new materials, ” says UTP Assoc Prof Dr Puteri Sri Melor Megat Yusoff.

Puteri leads the Materials Engineering programme at UTP – the bachelor's degree course introduced in September 2019 and the Foundation programme in January 2020.

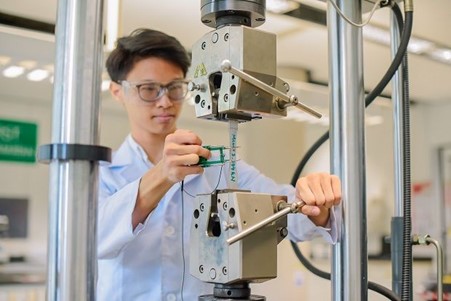

A UTP student is setting up a sample on a Universal Testing Machine (UTM). The UTM is used to test the tensile strength and compressive strength of materials, components and structures.

A UTP student is setting up a sample on a Universal Testing Machine (UTM). The UTM is used to test the tensile strength and compressive strength of materials, components and structures.

She says that at its heart, materials engineers investigate the relationship between the microstructure and properties of materials and how they are being processed.

“Microstructure includes atomic arrangement, atomic bonding, crystalline structure, to name a few.

"So, for every material, we try to understand the origins of its properties. For example, why is copper able to conduct electricity but not polymer? That’s because in the arrangement of the atoms and the type of bonding in copper, there are free electrons, which conduct electricity but in the case of polymers, these free electrons are not present so it cannot conduct electricity.

"Why is glass transparent? Why is metal opaque? That’s because the arrangement of the atoms will either allow the light to be passed through or reflected, depending on the crystalline arrangement and size of the material.

“So, the reason materials behave they way they do is due to their microstructure make-up, and once we understand that, then we can improve their performance and design new materials possessing the required properties.

"For example, if I want a material that can conduct electricity yet it’s very light and can dissipate heat I know what to do to the microstructure. I know what elements to include. Polymer, for example does not conduct electricity but if I put some copper powder in the polymer microstructure, then it begins to conduct electricity.

“In short, materials engineers design the desired microstructure in order to yield the properties they seek or to improve their performance, ” says Puteri who holds a Master of Science and Doctor of Philosophy in Polymers from Manchester University, UK.

The contributions of materials engineers are apparent in every facet of modern life, and they have a role to play in the manufacturing, automotive, oil and gas, electronics, pharmaceutical and biomedical sectors.

Fit-for-industry curriculum at UTP

As a new course offering at UTP, the Materials Engineering programme has been designed to meet industry needs.

“When we designed the curriculum we engaged with the industry and stakeholders, carving a niche which focused on advanced computing, modelling and degradation as well as failure of materials. The latter includes corrosion, a major concern in the oil and gas sector, ” she highlights.

UTP’s Materials Engineering programme also provides students with the state-of-the-art knowledge on smart materials and smart systems.

Smart structures are an emerging materials system that combines contemporary materials science with information science. The smart system is made up of sensing, processing, actuating, feedback, self-diagnosing and self-recovering subsystems.

The system uses the functional properties of advanced materials to achieve high performances with capabilities of recognition, discrimination and adjustification in response to a change of its environment.

Asked about the uniqueness of the UTP’s programme, she points out that it relates to the use of modelling and simulation using computational software.

“With the software we can tweak the arrangement of the atoms and we can predict the properties. Using these advanced tools in designing the product or enhancing the performance of the product, our students also gain that IT exposure and competency, ” she emphasises.

The university’s state-of-the-art lab facilities, its effective seven-month student industrial internship programme, and industry collaborations with partners in the oil and gas, automotive and manufacturing sectors further set UTP’s material engineering programme apart from others.

UTP, which is ranked 70th in the QS Asia University Rankings 2021 also has a high ratio of international community amongst the staff and students. This offers students a unique global intellectual and cultural experience.

“This is a course that will appeal to those with a strong science foundation. But more than that it’s for inquisitive minds and problem solvers who are keen on designing new things, those with the technical knowledge to invent something new or improve products, ” Puteri enthuses.