Digital solutions and innovation provider for businesses

(The Star, 6 August 2021)

Digitalisation is an often-quoted buzzword in recent years, but it wasn’t until the Covid-19 pandemic which began early 2020 that the digital transformation of organisations has become a vital component for businesses to meet the needs and challenges of the new normal environment.

Taking into account the issues and difficulties pertaining to digital transformation that contemporary businesses are facing, a private varsity has initiated proactive measures to assist them with their manpower, expertise and resources in achieving the switch to digital.

Universiti Teknologi PETRONAS (UTP) collaborates with relevant industries to develop and deliver solutions and innovations that address their pain points, optimise costs and improve processes.

Dr Lim Eu Shawn, who is the head of consulting and project delivery at UTP Technology Transfer Office (TTO), said that the pandemic has been a huge catalyst for digitalisation globally.

“A core component of Industrial Revolution 4.0 (IR4.0), digitalisation drives improvements in business, processes, and in the quality of delivery.

“If Malaysia wants to be a developed country, technology has to be at the forefront because otherwise we will be dependent on technologies from other countries.

“As an organisation that prides itself in state-of-the-art frontier research, UTP has always recognised the value of digitalisation,” he said.

The TTO is housed within the university’s Research, Innovation and Commercialisation (RIC) Division led by Prof Ir Dr Mohd Shahir Liew – the research business arm of the varsity.

“We deliver specialist consulting services to the industry – from desktop solutions to integrated project delivery for technology areas by leveraging on the expertise of the researchers,” Lim shared.

“But instead of developing the technologies and then selling them to industry, we listen to the industry’s pain points and learn about what’s ailing them. This way we’re able to then build solutions. That’s our business model,” he explained.

The university’s focus areas are in tandem with the technologies of IR4.0 and these include artificial intelligence (AI), big data analytics, cybersecurity, Internet of Things (IoT), cloud computing, smart devices, blockchain, and artificial reality and virtual reality.

To date, RIC has over 480 technologies in its inventory both digital and conventional in nature, of which around 20 are already commercialised.

“We have been actively applying all of these in oil and gas, and also other industries,” he revealed.

Solutions that create value for the industry

Digital solutions and innovations reduce or avoid cost, mitigate risk especially in the areas of health, safety and environment, and improve revenue streams by introducing optimisation and efficiency in an organisation’s processes.

“Through automation and digitalisation, we’re able to reduce the requirement for manned inspections or human dependent processes in the field.

“This avoids human errors (which translates to loss in efficiency and loss of revenue) and reduces repetitive, manual and laborious jobs,” Lim added.

One of the digital solutions already deployed is called Advance Diagnostic and Prognostic Technology (ADaPT) – developed with the national oil corporation, Petroliam Nasional Bhd (PETRONAS).

ADaPT replaces manual, conventional inspections by diagnosing and predicting mechanical equipment defects through continuous online monitoring. It offers accurate damage prediction based on machine learning of thermal, stress and creep damage patterns – detecting early signs of mechanical damage to predict an asset’s remaining life expectancy and avoid unplanned shutdown of plants.

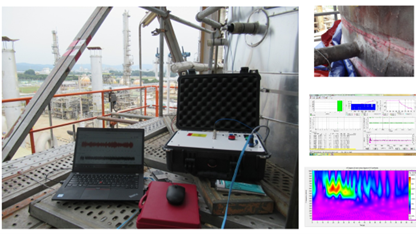

Deployment of ADaPT technology at PETRONAS plant to continuously monitor and predict creep crack failures in the equipment.

UTP has also partnered with PETRONAS GTS civil engineering fraternity to produce the Ultra Long Range Acoustic Technology (ULRAT) which can detect defects in oil and gas pipelines as far as 500 metres away with a high level of accuracy. This enables thousands of kilometres of essential pipeline networks to be monitored remotely and anticipate any failures or signs of it far in advance of any periodic maintenance.

Installation of ULRAT system at a critical hydrocarbon pipeline.

Another innovation, Poseidon, is an autonomous structural health monitoring system for offshore facilities, which capitalises on digital twinning and IoT.

“Going offshore is an extremely expensive affair. Whenever we need to inspect an offshore structure the cost is between RM500,000 and RM1mil per day due to cost-intensive underwater support.

“With Poseidon we deploy sensors coupled with a digital twin to find out what’s happening with the structure in real time and at all times,” he said, adding that the whole process is automated.

Poseidon system successfully commissioned at an offshore platform to monitor real-time structural condition.

Besides the development and delivery of solutions (from research and prototyping to pre-commercialisation and commercialisation), UTP also sees opportunities in post-commercialisation, which involves the transfer of technology to industry.

“Our goal is to be seen as a partner you can rely on for technology transfer, capacity building and at some point, as a sustainable business partner in the diversification of the business,” he added.